How to Improve Inventory Management? Top 10 Methods

Tarsem Singh | December 5, 2023 , 11 min read

Table Of Content

Inventory management is a critical aspect of running a successful business. Yet, many companies struggle to effectively manage their inventory, leading to issues such as stockouts, excess inventory, and financial inefficiencies.

In this comprehensive guide, we will explore top strategies and practical tips on how to improve inventory management and optimize your business operations.

Key Takeaways

- Effective inventory management boosts profitability, customer satisfaction, and overall operational efficiency.

- Accurate forecasting and data-driven insights prevent stockouts, overstocking, and optimize replenishment.

- Techniques like ABC analysis ensure high-value and fast-moving items get prioritized attention.

- JIT principles and optimized warehouse layouts lower holding costs, improve cash flow, and streamline fulfillment.

- Advanced analytics, BI dashboards, and continuous monitoring enable real-time decisions, reduce obsolete stock, and drive sustainable improvements.

Ways to Improve Inventory Management

1. Understanding the Importance of Inventory Management

Inventory management is more than just keeping track of stock levels. It directly impacts your business’s profitability, customer satisfaction, and overall operational efficiency. By effectively managing your inventory, you can reduce costs, minimize stockouts, optimize cash flow, and improve customer service.

Also Read: Using PowerApps To Inventory Management

2. Prioritizing Accurate Demand Forecasting

One of the key pillars of effective inventory management is accurate demand forecasting. By understanding customer demand patterns, seasonal fluctuations, and market trends, you can make informed decisions about stock levels and replenishment strategies.

Utilize advanced analytical tools and techniques to analyze historical sales data, customer behaviour, and market insights. This data-driven approach will enable you to forecast demand with greater accuracy, reducing the risk of overstocking or understocking.

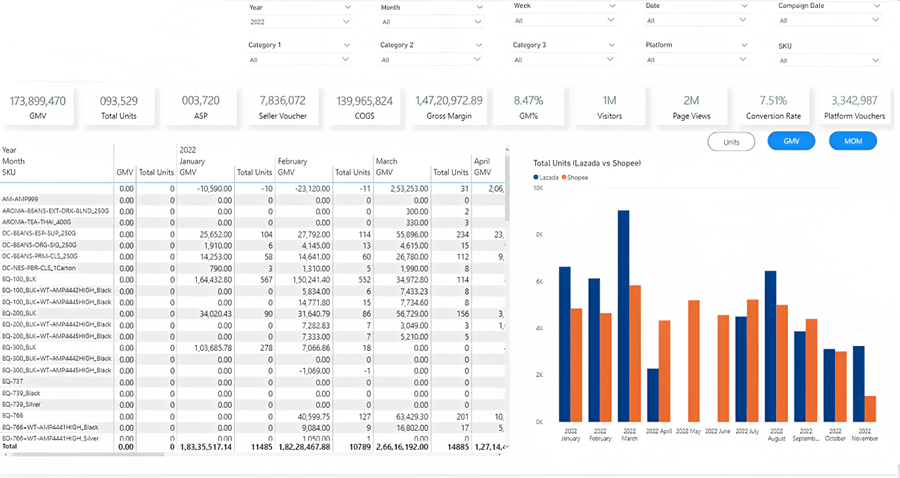

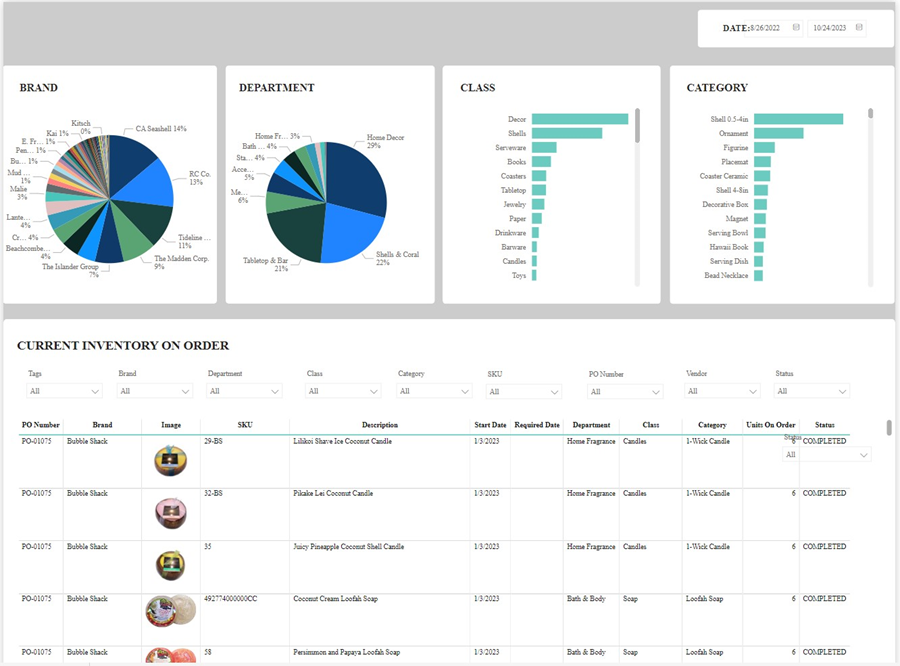

A sample report to analyze the sales data at various levels

The above report shows the sales data in terms of units and GMV for all the SKUs and this report can be filtered at various levels for better analysis. There are slicers for product categories, SKUs, selling platforms, etc.

3. Utilizing Advanced Analytical Tools

In today’s data-driven world, leveraging advanced analytical tools is essential for inventory management success. Inventory management software, powered by artificial intelligence and machine learning algorithms, can provide valuable insights into inventory optimization, demand forecasting, and supply chain efficiency.

These tools can automate repetitive tasks, such as data entry and inventory tracking while providing real-time visibility into stock levels and order fulfilment. By harnessing the power of analytics, you can make data-backed decisions that drive inventory improvement and operational excellence.

A better way to do this working with a service provider that can integrate data from different inventory data management tools like Quickbooks, Cin7, Unleashed, Lightspeed, etc. and generate reporting insights from a combined database.

To read a similar case study, click here

4. Categorizing Inventory for Better Control

To effectively manage your inventory, consider categorizing your products based on their value, demand, and turnover rate. This categorization helps prioritize stock control efforts and determine the appropriate ordering quantities and frequencies.

One popular categorization method is the ABC analysis, which classifies items into three groups: A, B, and C. Group A consists of high-value items with lower demand but higher profitability. Group C includes low-value items with high demand and faster turnover. Group B falls in between, with moderate value and demand.

By categorizing your inventory, you can allocate resources more efficiently, optimize stock levels, and focus on managing high-value items while still meeting customer demands for lower-value products.

5. Implementing Just-in-Time (JIT) Inventory Management

Just-in-Time (JIT) inventory management is a strategy that aims to minimize inventory levels by ordering and producing goods only when needed. This approach reduces holding costs, maximizes warehouse space, and improves cash flow.

JIT requires close coordination with suppliers, ensuring timely deliveries and accurate order fulfilment. By synchronizing production schedules and order quantities with customer demand, you can avoid overstocking and reduce the risk of obsolete inventory.

JIT is particularly beneficial for industries with perishable goods or rapidly changing market demands. Implementing JIT principles can lead to significant cost savings and operational efficiencies.

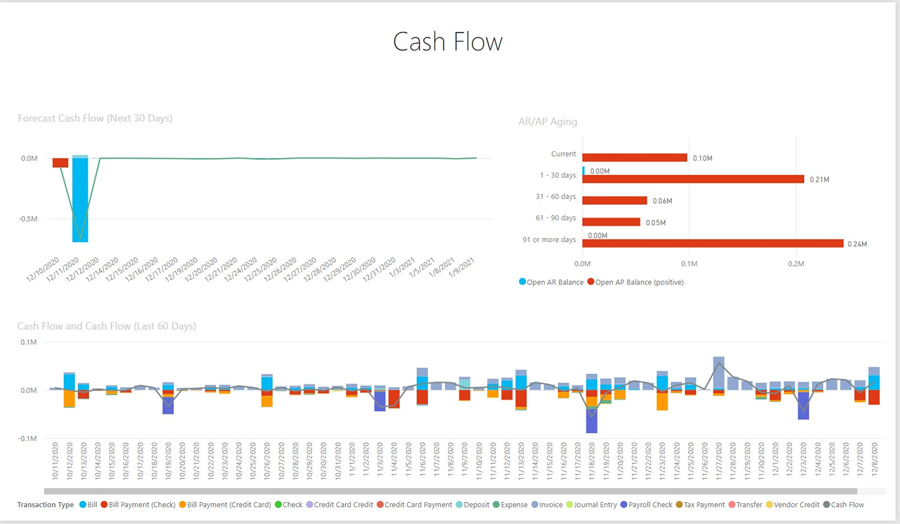

This further ensures continuous cash flow in the business and you can create a report to monitor the regular cash flow. For example:

6. Optimizing Warehouse Layout and Organization

A well-organized warehouse layout is crucial for efficient inventory management. By optimising your warehouse design, you can enhance inventory visibility, streamline order fulfilment processes, and minimize errors.

Consider grouping similar products and designating specific areas for different inventory categories. This organization system improves picking and packing efficiency, reduces search times, and enables accurate stock counts.

Additionally, invest in technology such as barcode scanners and RFID tags to track inventory movements in real time. These tools enhance inventory accuracy, automate data capture, and facilitate efficient warehouse operations.

7. Automating Inventory Processes with Technology

In today’s digital age, manual inventory management processes are prone to errors, time-consuming, and inefficient. Embrace technology solutions to automate critical inventory processes and improve overall efficiency.

Inventory management software offers features such as real-time tracking, automated order generation, and demand forecasting. These tools integrate with other business systems, such as point-of-sale (POS) and supply chain management, providing end-to-end visibility and control.

This can be easily done using APIs of different tools used by your business. Data from all these tools will be fetched and stored in a data warehouse hosted on your server.

By automating inventory processes, you can reduce human errors, save time, and focus on strategic tasks that drive business growth.

8. Establishing Effective Communication Channels

Effective communication is vital for successful inventory management. Collaboration between different departments, suppliers, and customers is essential for accurate demand planning, order fulfilment, and supply chain coordination.

Ensure clear lines of communication between sales, operations, and procurement teams. Regularly share sales forecasts, inventory updates, and production schedules to align expectations and optimize inventory levels.

Furthermore, establish strong relationships with suppliers and maintain open lines of communication. Proactive communication with suppliers helps address issues promptly, mitigate supply chain disruptions, and ensure timely deliveries.

9. Regularly Auditing and Evaluating Inventory

Regular inventory audits are crucial for maintaining accurate inventory records and identifying areas for improvement. These audits involve physically counting and reconciling stock levels against recorded data.

Conduct comprehensive audits at regular intervals to minimize inventory discrepancies, uncover inefficiencies, and identify opportunities for process optimization. Use auditing as a tool to evaluate the effectiveness of your inventory management system and make necessary adjustments.

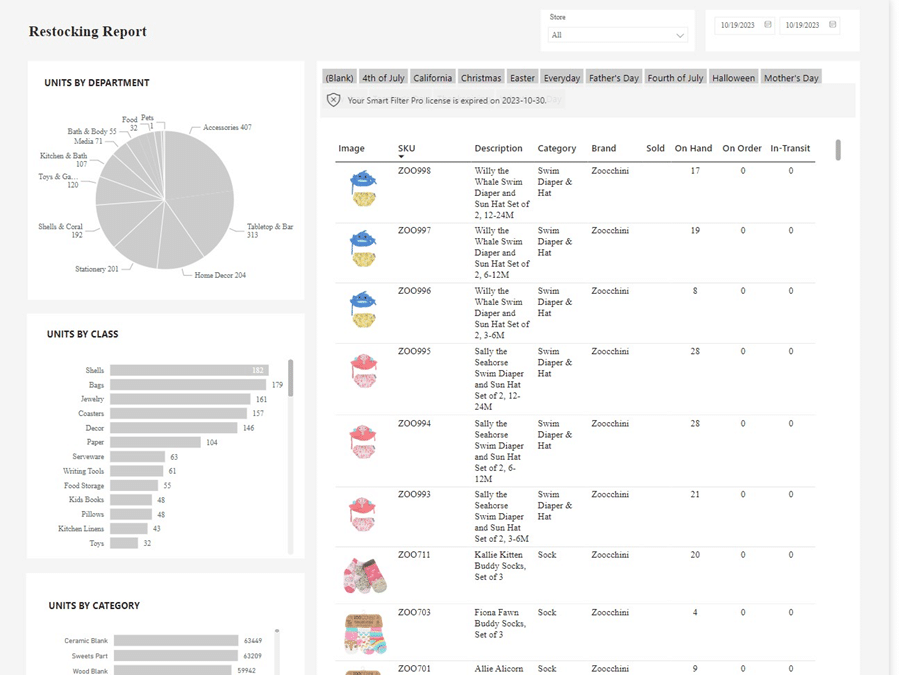

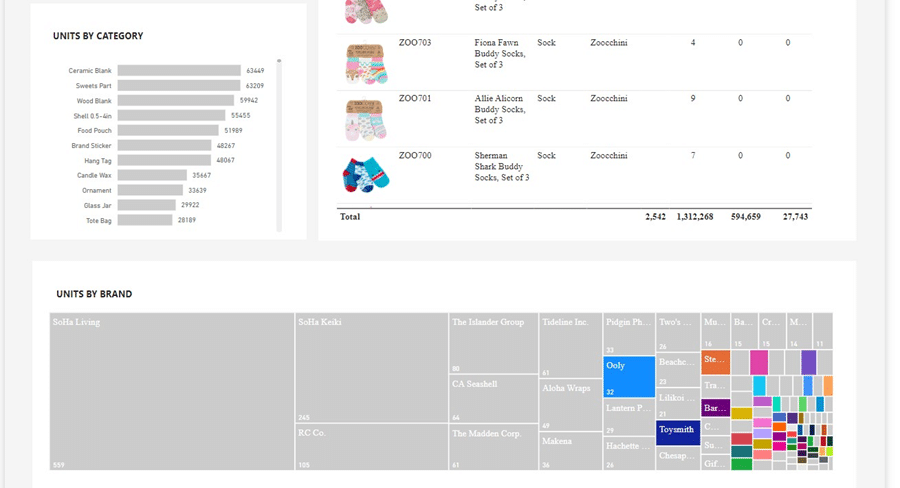

The below dashboards can be used to have real-time information about the Inventory on order quantity and Restocking data:

10. Actionable Insights from Data Analysis

Data analysis plays a pivotal role in driving inventory improvement. Leverage advanced analytics techniques to gain actionable insights into customer behaviour, market trends, and supply chain performance.

By analyzing historical sales data, you can identify patterns, seasonal trends, and demand fluctuations. This information helps fine-tune your inventory management strategies, optimize stock levels, and align production schedules with customer demand.

Invest in inventory management software that provides robust reporting and analytics capabilities. These tools generate in-depth reports, visualizations, and predictive analytics, enabling data-driven decision-making and continuous improvement.

Case Study: A Thailand-based Wholesaler dealing in electronic goods was selling its products from multiple sources/platforms like Lazadda, Shopee, Offline sales, etc. The higher management of the company needed to see actionable insights from all these platforms in one dashboard. They wanted to analyze the performance of different products/categories at different platforms and which platform/product category/demography is most profitable to them. Further, they used to run flash sales campaigns with discounts during festivals and wanted to analyze the sales of different products during this campaign period.

How ScaleupAlly fulfilled the above requirements: Read the case study here

11. Managing Excess and Obsolete Inventory

Excess and obsolete inventory can tie up valuable resources and impact your bottom line. It is crucial to have processes in place to identify, manage, and reduce excess stock.

Regularly assess inventory levels, sales data, and product lifecycle stages to identify slow-moving items or items nearing obsolescence. Take proactive measures to sell off excess stock through promotions, discounts, or targeted marketing campaigns.

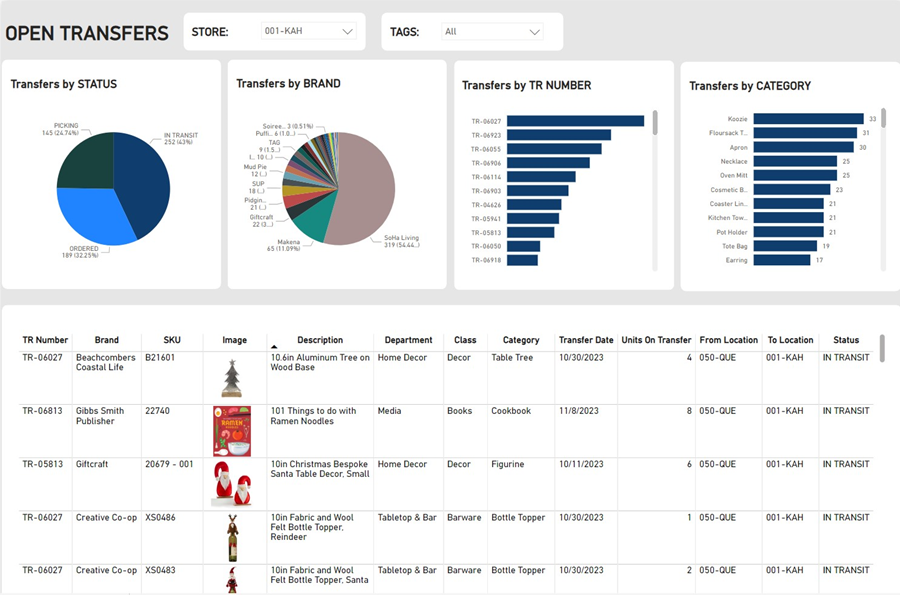

Stock Transfer Approach: If there are multiple stores, the excess stock can be transferred from one store to another store for effective utilization of the available stock. The same can also be monitored using BI reports.

For example, below is one report showing a summary of the SKU transfers:

In conclusion, proactive management of excess and obsolete inventory is essential for optimizing resources and maintaining profitability. By regularly assessing inventory levels, utilizing strategies such as promotions and stock transfers, and leveraging business intelligence tools, businesses can effectively mitigate the risks associated with excess stock and improve overall inventory management efficiency.

Also Read: How to use Power BI for Inventory Management?

Real-Life Examples and Success Stories

Real-life examples illustrate how businesses have successfully improved their inventory management processes. Let’s explore a few inspiring stories:

- Company XYZ, a retail chain, implemented advanced inventory management software that integrated with its POS system. This integration provided real-time inventory visibility, reduced stockouts, and improved customer satisfaction.

- Manufacturer ABC adopted just-in-time principles and collaborated closely with suppliers to synchronize production schedules. This strategy resulted in significant cost savings, reduced lead times, and improved supply chain efficiency.

- E-commerce retailer DEF leveraged data analytics to identify customer demand patterns and optimize stock levels. By accurately forecasting demand and adjusting inventory accordingly, they minimized excess inventory and maximized profitability.

These examples demonstrate the transformative power of implementing inventory management best practices and leveraging innovative technologies.

Conclusion: Taking Your Inventory Management to the Next Level

Improving inventory management is crucial for optimizing business operations, reducing costs, and enhancing customer satisfaction. By implementing strategies such as accurate demand forecasting, utilizing advanced analytical tools, and optimizing warehouse layout, you can significantly improve inventory management.

Embrace technology solutions, automate processes, and establish effective communication channels to streamline inventory operations and maximize efficiency. Regularly audit and evaluate inventory, analyze data, and manage excess stock to optimize your inventory management practices continuously.

By adopting these best practices and learning from real-life success stories, you can take your inventory management to the next level and drive sustainable business growth. Start implementing these strategies today and unlock the full potential of your inventory management processes.

Frequently Asked Questions

Q: How can analytics help in improving inventory management?

Analytics provides valuable insights into customer behaviour, demand patterns, and supply chain performance. By analyzing data, businesses can make informed decisions, optimize stock levels, and improve overall inventory management efficiency.

Q: What are some inventory improvement ideas for small businesses?

For small businesses, implementing inventory management software, adopting JIT principles, and prioritizing accurate demand forecasting are key strategies. Additionally, optimizing warehouse layout, automating inventory processes, and establishing effective communication channels can significantly improve inventory management.

Q: How can I measure the success of my inventory management improvements?

Key performance indicators (KPIs) such as inventory turnover ratio, stockout rate, and order fulfilment time can help measure the success of inventory management improvements. Regularly track and analyze these metrics to assess the effectiveness of your inventory management strategies.

Q: Is it possible to bring all the data from any inventory management tool that I am using into the BI reports?

Yes, it is possible. These tools have their APIs using which we can connect with your data and fetch it in nearly real-time to build insightful dashboards.

Related Blogs

Data Warehouse Cost Breakdown: Factors, Pricing Models & Platform Comparison

Discover how much a data warehouse costs in 2025. Explore pricing models, key factors, and platform comparisons to plan your data budget effectively.

Tarsem Singh

Nov 6 ,

14 min read

How Much Do Integrations Cost? [Pricing Breakdown & Key Insights]

Learn how much integrations cost, key factors influencing pricing, hidden expenses to avoid, and effective ways to reduce integration costs.

Tarsem Singh

Nov 6 ,

9 min read

Power BI for Inventory Management: A Comprehensive Guide

Explore the hidden power of Power BI for inventory management and how it provides businesses with powerful analytics and visualization capabilities.

Tarsem Singh

Oct 8 ,

19 min read